How To Get A Stripped Bolt

A stripped or threaded nut or bolt can be a cause of unbelievable frustration. Time can easily be lost when it means an unwanted trip to the fastener specialist, or worse still, if the thread in question isn't that easily replaceable.

Thankfully, tool manufacturers have considered this, and come up with a range of options to get your task back on track. So what tools are available to repair a damaged thread?

Tap and Die Set

This one you may have heard of before. These can be purchased as metric or imperial sets if you only use one or the other; or as a massive combination set with taps and dies to cover all bases. Inside the kit you'll find taps for repairing and creating inside threads, and dies for repairing and creating outside threads. Each of these is marked with the thread size and pitch it is designed to work with.

You'll also find a die handle and tap wrench which each of these pieces can slot into, and the combination set contains thread pitch gauges to help you determine which tap or die you need.

How to Use a Tap & Die Set

Step 1:

To repair an outside thread like a bolt or stud, first ensure it is fixed tightly in place or in a bench vice.

Step 2:

Use a thread pitch gauge to determine which die you need, or very carefully match the die to the thread by trialling different ones; then fit the die into a die handle.

Step 3:

Lubricate the thread with a thick lubricant such as motor oil, then begin winding the die down upon the thread. Pay very close attention to getting the die on straight for the first few turns at least.

Commence the thread cutting using firm and even pressure - with a quarter turn clockwise, followed by a quarter turn anti-clockwise to clear the metal shavings from the thread.

Step 4:

Repairing an internal thread using a tap occurs in much the same way. The bolt which originally came out can be used to determine the thread size.

Step 5:

With a little lubricant applied to the tap and thread the tap must be carefully wound in using the same quarter turn in, quarter turn out method as used with the die.

Great! But what if the thread is too large to be repaired with a die?

Some threads are too large or awkward to repair with a tap and die set, but all hope is not lost when there's a thread repair file in your kit! Again you can purchase one for metric and one for imperial thread patterns. Fastener size does not matter when using a thread file, due to the nature of how you use it, which goes like this: Step 1: Step 2: Step 3: With these tools in your collection, you'll barely bat an eyelid at stripped or damaged threads. You can even use a tap piece to create a brand new threaded hole, or a die to craft a bolt for very specific applications.

Thread Repair File

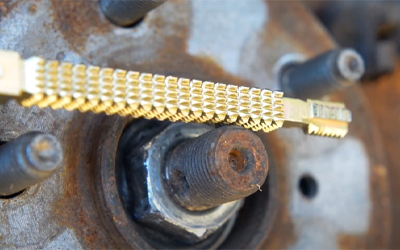

How to Pick a Thread Repair File

Determine the correct thread pitch to use by testing different sides of the file against an undamaged section of thread. You'll know you've got the right one when the file sits perfectly between the ridges of the thread, and no light comes between the file and the threads.

Now, begin filing with medium pressure on a section of thread just next to the damage and work your way across.

Run a nut over the thread periodically and keep filing until the nut runs smoothly over the damaged section.Stripped thread? No worries!

How To Get A Stripped Bolt

Source: https://www.supercheapauto.com.au/blog/how-to/tools-workshop/fixing-a-stripped-bolt-or-nut-thread.html

Posted by: caronrancelf1965.blogspot.com

0 Response to "How To Get A Stripped Bolt"

Post a Comment